Lubrication

Automated Solutions for Production and Assembly Processes

In production and assembly processes, lubrication are integral parts of many workflows. In many cases, this is still done entirely by hand, for example with brushes or tubes. However, applying with the help of suitable lubrication systems is more reliable.

Versatile Applications

This includes both applying lubricant to components and filling bearings, gearboxes, or engines. The simplest solution is the use of metering valves with a handle for applying lubricants. Handling is still done entirely by the worker, but the applied amount is precisely defined and reproducible.

Semi-Automatic Lubrication Stations

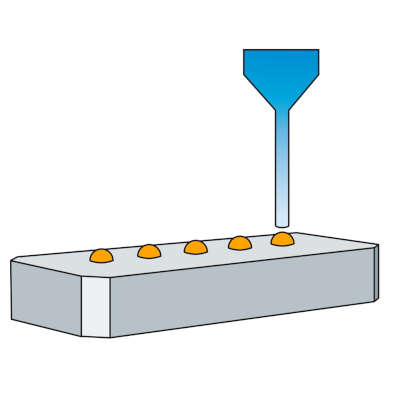

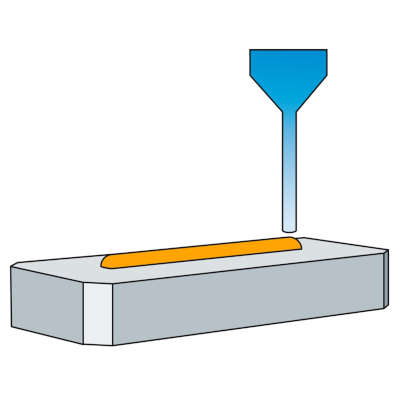

With simple table-top lubrication stations, equipped with an applicator tailored to the component to be lubricated, the application can already be semi-automatic. This applicator ensures that the grease is applied exactly where it is needed.

Contactless Application

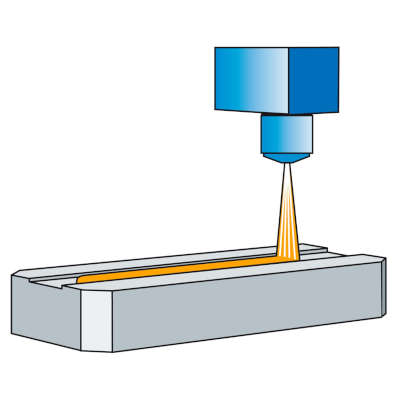

If contactless application of the lubricant is necessary, this can be done by spraying, injecting, or jetting.

Complex Workpieces and Integration into Production Lines

For more complex workpieces, lubrication stations with multiple applicators and feeding via pneumatic cylinders are used. Here, the worker only inserts the component and starts the dosing process. For large quantities, the metering system can also be integrated into a production line, for example, with metering valves mounted on robots or a meterin station for continuous workpieces.