Metering Systems

Improve your production!

- Efficiency and Quality: metering systems enable precise and efficient metering, leading to higher quality and reduced material usage

- Safety: They reduce employee contact with cheimicals and simplify the dosing process

- Environmental Protection: Less material consumption and waste contribute to environmental protection

- Flexibility: Suitable for various media such as grease, oil, adhesives, sealants, and potting comounds. Option include vacuum, heating or stirring

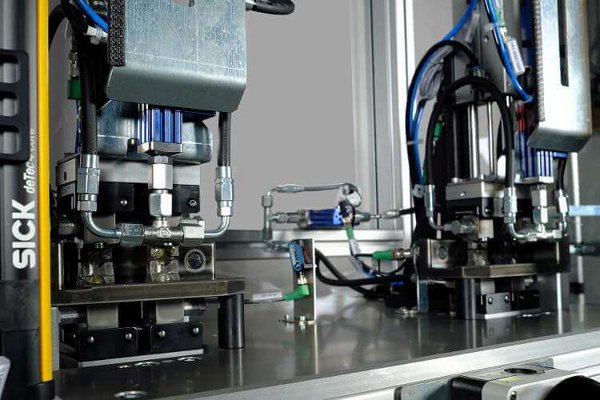

Our product range

- Mixing and metering systems for 2-component materials

- Volumetric metering systems for 1-component materials

- Volumetric metering valves for oil and greases

- Time-Pressure Dispensing for Oils, Greases, Sealants, and Adhesives

Application

Our dispensing systems are used for a wide range of tasks, including:

- bonding

- potting

- sealing

- filling

- lubricating

The user-friendly operation of our systems is ensured by intuitive interfaces that offer extensive options for service and maintenance.

Flexible use

Our dispensing systems can be designed for manual, semi-automatic, or fully automatic use and are suitable for a wide range of industries, including:

- automotive industry

- electrical engineering and electronics

- medical technology

- mechanical and plant engineering

Dispensing quantities range from the tiniest droplets to several hundred kilograms, for example when filling a large bearing with grease.

Materials

Our systems are highly flexible and capable of handling both low- and high-viscosity or paste-like media, with or without fillers. Optional features such as vacuum, heating, or agitators can be added to optimally prepare the media.

Precise Material Application

Material can be applied in dots, beads, or over a surface - for example, by spraying. The dosing quantity and speed are controlled either by time and pressure or volumetrically.

Contact us today for a consultation or find more information about our dispensing systems on our website!