Lubrication

Lubricating is part of many production and assembly processes.

Today most common is completely manual lubrication e.g. by using brushes. The amount of lubricant varies, and bristles or other impurities can stick on the product. This process can be done cleaner and more reliable by using metering equipment.

We offer metering valves with handles where the workers still apply the lubricant by hand, dispensing stations for a defined application of lubricant and automated solutions.

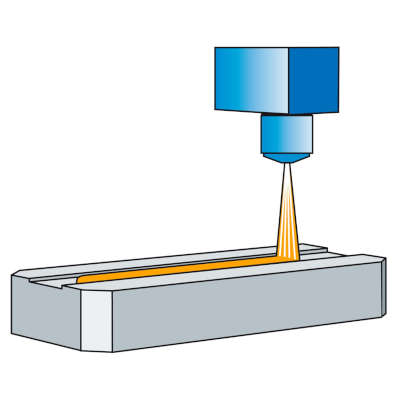

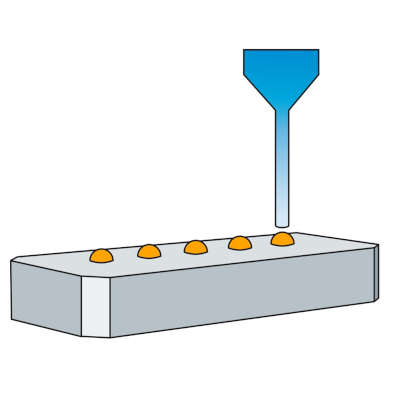

Contactless application is also possible by spraying or pulsing.

The lubrication system can also be integrated in an automated production line.

Metering and application

Lubrication processes contain the tasks material supply, metering and application.

Depending on material and process data there are different possible ways to handle the task. In some cases a system based on material pressure and dispensing time will produce good results. The amount of lubricant can be adjusted by pressure and time.

For more accurate processes volumetric metering devices are the best choice.

We offer different types of metering valves, dispensing valves, spray valves, applicators etc.

Material supply is possible by using drum pumps, cartridges or pressure tanks.

![Dosierraupe [Translate to English:] Dosierraupe](/fileadmin/images/Dosierraupe.jpg)